Baoshili Ultra-Clean PFA Fitting

Recently, Baoshili‘s semiconductor-grade ultra-clean PFA fitting “1/2” butt-weld tee” successfully passed performance tests including roughness and metal ion leaching, meeting SEMI F57 specifications. As a key model in the company’s semiconductor-grade PFA fitting product lineup, it not only marks Baoshili’s breakthrough in the field of high-purity fluid core components but also supports the company in building an integrated solution for semiconductor-grade chemical delivery systems.

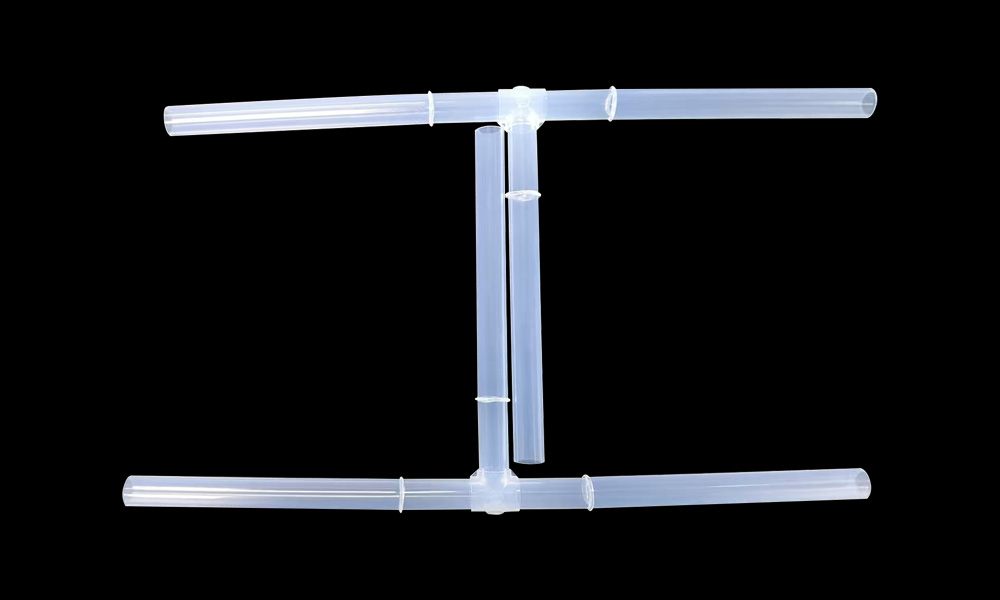

In advanced manufacturing processes, metal contamination control has become a critical factor determining chip performance. Ultra-pure PFA materials are core components for chemical delivery in semiconductor front-end manufacturing. Baoshili's 1/2" ultra-clean PFA butt-weld tee features ultra-high cleanliness and excellent acid/alkali resistance. It forms a T-shaped connection, facilitating the distribution or convergence of multi-path fluids, and is widely used in complex pipeline systems for semiconductor manufacturing.

Through proprietary patented manufacturing processes, the product has achieved breakthroughs in multiple indicators:

Ultra-Low Metal Ion Leaching

Metal contamination can alter the electrical properties of microelectronic devices and cause corrosion or etching on key surfaces during manufacturing, leading to device failure. The metal ion leaching levels of Baoshili's 1/2" ultra-clean PFA butt-weld tee—including aluminum (Al), arsenic (As), antimony (Sb), cadmium (Cd), chromium (Cr), copper (Cu), iron (Fe), lead (Pb), lithium (Li), magnesium (Mg), manganese (Mn), nickel (Ni), sodium (Na), titanium (Ti), tin (Sn), vanadium (V), and zinc (Zn)—all meet SEMI F57 standards, satisfying the extreme contamination control requirements of advanced processes.

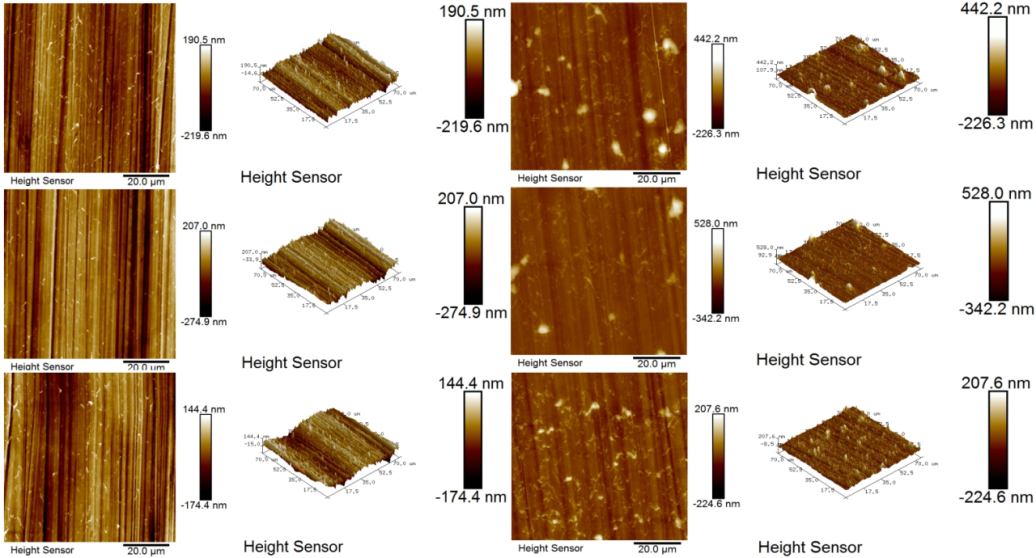

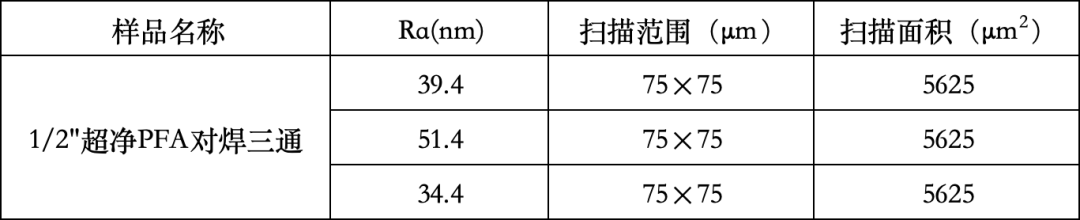

Ultra-Smooth Inner Wall

With an inner surface roughness of Ra ≤ 0.35μm, it prevents fluid retention and scaling, reducing contamination risks.

It maintains stable chemical properties within a temperature range of -40℃ to 260℃.

Corrosion Resistance

It resists corrosive chemicals such as strong acids (hydrofluoric acid, nitric acid) and strong alkalis (ammonia water), with no metal migration over long-term use.

Integrated Hot-Melt Welding

The ultra-clean PFA fitting forms a molecular-level bond with ultra-clean PFA pipes through hot-melt welding, creating a complete chemical delivery system and ensuring the purity and stability of semiconductor manufacturing processes.

Currently, only a few domestic enterprises have developed semiconductor-grade ultra-pure fluoropolymer products. Through independent R&D, Baoshili has overcome key technologies such as high-purity material purification and precision molding, successfully launching semiconductor-grade products including the 1/2" ultra-clean PFA butt-weld tee and multiple models of ultra-clean PFA pipes, which are widely used by leading semiconductor enterprises.

As the global semiconductor industry advances into the 3nm era, "nanoscale contamination control" in chemical delivery systems has become a critical bottleneck restricting yield rates. Baoshili is continuously increasing R&D investment in high-purity fluoropolymer products and actively collaborating with industry partners to formulate the group standard Semiconductor-Grade Ultra-Pure Melt-Processible Polytetrafluoroethylene (PFA) Pipes, aiming to accelerate the development of domestic semiconductors.