Aluminum Structural Shapes: Types, Properties & Dimensions You Need to Know

Introduction: What Are Aluminum Structural Shapes?

Aluminum structural shapes are integral components across a myriad of industries, offering unparalleled versatility and functionality. From the towering skyscrapers in urban landscapes to the sleek, aerodynamic designs of modern aircraft, aluminum shapes are the backbone of innovative construction and manufacturing processes. Their unique properties make them indispensable in sectors such as construction, aerospace, and automotive, where their lightweight yet robust nature is highly valued.

In construction, aluminum shapes like beams, channels, and angles are favored for their strength-to-weight ratio, which allows for the creation of sturdy structures without the burden of excessive weight. This attribute not only reduces the load on foundations but also facilitates easier handling and faster assembly, leading to more efficient building processes. Imagine the ease of erecting a high-rise building with components that are both strong and light, contributing to faster project completion and reduced labor costs.

In the aerospace industry, the demand for materials that can withstand extreme conditions while minimizing weight is critical. Aluminum structural shapes meet these demands by providing the necessary strength and durability without compromising on weight, thus enhancing fuel efficiency and performance. Similarly, in the automotive sector, aluminum shapes are employed to create lighter vehicles, which translates to improved fuel economy and reduced emissions, aligning with the growing focus on sustainability.

Understanding the properties and dimensions of these aluminum shapes is crucial for selecting the right type for specific applications. Whether it's for constructing a bridge, designing an aircraft, or manufacturing a car, knowing the precise specifications ensures structural integrity and optimal performance. As industries continue to evolve, the role of aluminum structural shapes in driving innovation and efficiency remains more significant than ever.

Types of Aluminum Structural Shapes

When it comes to structural applications, the versatility of aluminum is unmatched, thanks to its array of available shapes. These aluminum structural shapes are the building blocks of countless construction and manufacturing projects, offering both standard and custom options to meet diverse needs.

Standard Aluminum Structural Shapes

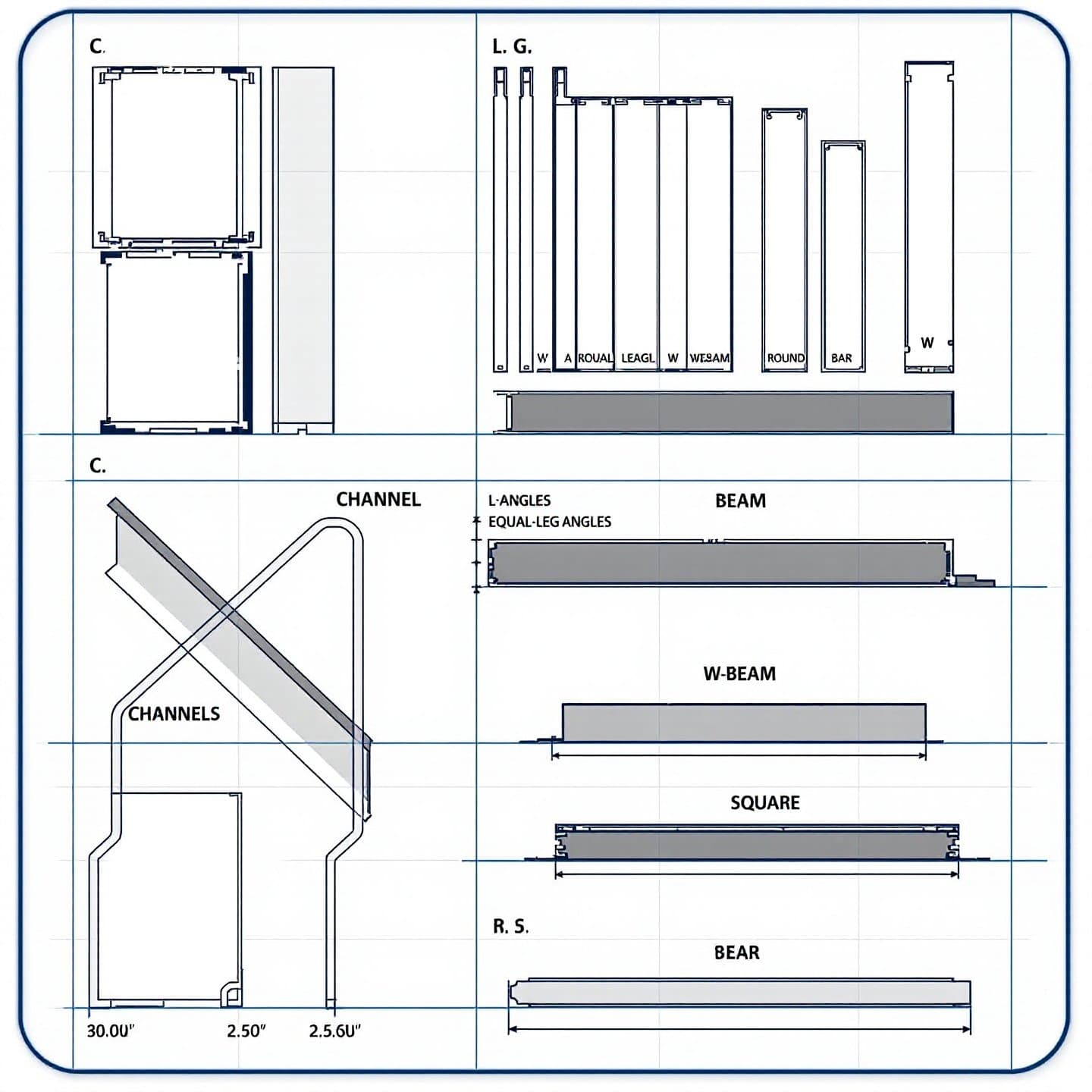

Standard aluminum structural shapes include channels, angles, beams, and bars. These shapes are commonly used in construction projects for their ease of use and availability. For instance, aluminum channels are often utilized for framing and support structures due to their ability to bear significant loads while maintaining a lightweight profile. Similarly, aluminum angles are popular in reinforcing corners and edges, providing stability and strength without adding unnecessary weight.

Aluminum beams, such as I-beams and H-beams, are integral in load-bearing applications. Their design allows them to support substantial weight, making them ideal for frameworks and bridges. Bars, on the other hand, are versatile components used in various applications, from simple reinforcements to complex support systems. The availability of these shapes in standard dimensions ensures that they can be readily incorporated into any project, saving time and reducing costs.

Extruded Aluminum Structural Shapes

For projects that demand unique specifications, extruded aluminum structural shapes offer a customizable solution. The extrusion process involves pushing aluminum through a die to create a specific cross-sectional profile, allowing for the creation of complex and precise shapes tailored to individual project requirements. This process not only supports the development of innovative designs but also enhances the material's strength by concentrating it where needed most.

The benefits of extruded aluminum shapes extend beyond customization. They are lightweight, yet strong, and their seamless construction reduces the need for mechanical joints, minimizing potential weak points. These attributes make them especially advantageous in industries like aerospace and automotive, where precision and performance are paramount. Moreover, the extrusion process is efficient, ensuring quick turnaround times and facilitating faster project completion.

In summary, whether opting for standard aluminum structural shapes or exploring the possibilities of extruded designs, the choice of shape plays a crucial role in the success of any structural application. Understanding the specific needs of your project and selecting the appropriate aluminum shape can lead to enhanced performance, cost efficiency, and innovation.

Aluminum Structural Shapes Dimensions and Sizes

When selecting aluminum structural shapes for a project, understanding the dimensions and sizes available is crucial to ensuring both structural integrity and efficiency. The dimensions of these shapes can significantly impact their performance, making it essential to choose the right size for your specific needs.

Understanding Aluminum Structural Shapes Dimensions

Aluminum structural shapes come in a variety of dimensions, tailored to meet the diverse requirements of different projects. These dimensions typically include width, height, and thickness, which together define the shape's cross-sectional profile. For instance, channels and beams are measured by their height and flange width, while angles are defined by their leg lengths and thickness.

The extrusion process allows for the creation of shapes with precise dimensions, ensuring consistency and reliability in their application. This precision is vital for maintaining the structural integrity of the shape, especially in load-bearing applications where even slight deviations can lead to significant issues.

Choosing the Right Size for Your Project

Selecting the appropriate size of aluminum structural shapes involves considering the specific demands of your project. For example, thicker walls may be necessary for applications requiring enhanced strength and load-bearing capacity, while thinner profiles might be preferred for projects where weight reduction is a priority. The standard dimensions available in the market often cater to common applications, but custom sizes can be produced through extrusion for unique requirements.

Moreover, the length of the aluminum shape can also be a critical factor. Standard lengths are readily available, facilitating easy integration into existing designs and reducing the need for additional processing. However, custom lengths can be ordered to ensure a perfect fit for specific applications, minimizing waste and optimizing material usage.

In conclusion, understanding the dimensions and sizes of aluminum structural shapes is fundamental to their effective use in any project. By carefully considering the dimensional requirements and selecting the appropriate size, you can enhance the efficiency, safety, and success of your structural applications.

Aluminum Structural Shapes Catalog: A Handy Reference

When embarking on a construction or design project, having a comprehensive aluminum structural shapes catalog at your disposal can be invaluable. This catalog serves as a detailed guide to the wide array of aluminum shapes available, providing crucial information on specifications, dimensions, and material properties. By utilizing such a catalog, you can ensure that you select the most suitable materials for your specific needs, enhancing both the efficiency and effectiveness of your project.

Imagine you're tasked with designing a lightweight yet robust framework for a new building. The catalog becomes your go-to resource, offering insights into the various types of aluminum profiles, such as channels, angles, and beams. Each entry typically includes detailed descriptions, technical drawings, and precise measurements, allowing you to compare options and choose the best fit for your design requirements. This level of detail not only aids in making informed decisions but also facilitates communication with suppliers and contractors, ensuring everyone is on the same page.

How to Use the Catalog Effectively

To make the most of an aluminum shapes catalog, start by clearly defining the requirements of your project. Consider factors such as load-bearing capacity, environmental conditions, and aesthetic preferences. With these criteria in mind, browse through the catalog, focusing on the sections that align with your needs. Pay attention to the technical specifications and material properties listed for each shape, as these will guide you in selecting the optimal components.

Additionally, many catalogs, like those from Extrude-A-Trim , offer insights into the availability of custom extrusions, which can be particularly beneficial if your project demands unique dimensions or designs. By leveraging the catalog's resources, you can streamline the selection process, reduce errors, and ultimately contribute to the success of your project.

In summary, an aluminum structural shapes catalog is more than just a list of products; it is a strategic tool that supports effective decision-making and project planning. By understanding how to navigate and utilize this resource, you can ensure that your project benefits from the most suitable and efficient aluminum solutions available.

Understanding the Properties of Aluminum Structural Shapes

Aluminum structural shapes are renowned for their unique properties that make them ideal for a wide range of applications. These properties include lightweight, high strength-to-weight ratio, corrosion resistance, and sustainability, all of which contribute to their popularity in industries like construction, aerospace, and automotive. Let's delve deeper into these characteristics to understand why aluminum is often the material of choice for structural applications.

Lightweight and High Strength-to-Weight Ratio

One of the most significant advantages of aluminum is its lightweight nature. Despite being approximately one-third the weight of steel, aluminum offers a high strength-to-weight ratio, making it an excellent choice for applications where reducing weight is crucial. This property is particularly beneficial in the aerospace and automotive industries, where lighter materials can lead to improved fuel efficiency and performance. Imagine designing an aircraft or vehicle that is not only strong but also significantly lighter, enhancing both speed and fuel economy.

Corrosion Resistance

Another critical property of aluminum is its natural resistance to corrosion. When exposed to air, aluminum forms a thin oxide layer that protects the underlying metal from further oxidation. This feature makes aluminum structural shapes highly durable and suitable for use in environments where they are exposed to moisture or other corrosive elements. For instance, in construction, aluminum's corrosion resistance ensures the longevity of structures, reducing maintenance costs and extending their lifespan.

Sustainability

Aluminum is also celebrated for its sustainability. It is one of the most recyclable materials available, with a recycling process that requires only about 5% of the energy needed to produce primary aluminum from bauxite ore. This recyclability not only conserves natural resources but also reduces environmental impact, making aluminum a sustainable choice for eco-conscious projects. According to the Aluminum Association , recycling aluminum significantly decreases greenhouse gas emissions, contributing to a more sustainable construction industry.

In conclusion, the properties of aluminum structural shapes—lightweight, strength, corrosion resistance, and sustainability—make them indispensable in modern engineering and design. These attributes not only enhance the performance and longevity of structures but also align with the growing emphasis on sustainability in material selection. Understanding these properties allows engineers and designers to make informed decisions, ensuring that their projects benefit from the best that aluminum has to offer.

How to Choose the Right Aluminum Structural Shape for Your Project

When embarking on a project that requires aluminum structural shapes, selecting the right type is crucial to ensure both efficiency and effectiveness. The process involves evaluating several key factors, each of which plays a significant role in determining the best aluminum shapes for your specific needs. Let’s explore these considerations to help you make an informed decision.

Assessing Load-Bearing Capacity

One of the primary factors to consider is the load-bearing capacity of the aluminum shape. Different shapes, such as beams, channels, and angles, offer varying levels of strength and support. For instance, I-beams are excellent for heavy load applications due to their design, which efficiently distributes weight. Conversely, for lighter loads, an angle or channel might suffice, offering the necessary support without excessive material use.

Evaluating Environmental Conditions

The environment in which the aluminum shape will be used is another critical consideration. Aluminum's natural corrosion resistance makes it suitable for outdoor and marine applications where exposure to elements is a concern. However, specific alloys like 5052 are particularly resistant to marine environments, making them ideal for coastal or industrial settings. Understanding the environmental conditions will guide you in choosing the best aluminum shapes for projects exposed to harsh elements.

Balancing Cost and Budget

Cost is always a factor in project planning, and it’s essential to balance budget constraints with performance requirements. While custom extrusions might offer the perfect fit for unique designs, they can be more expensive than standard shapes. Therefore, it’s vital to weigh the benefits of customization against the potential increase in cost. Standard shapes often provide a cost-effective solution, especially when they meet the project's requirements without modification.

Consulting with Structural Engineers

For large-scale or complex projects, consulting with structural engineers can provide invaluable insights. These professionals can assess the specific demands of your project, recommend the most suitable aluminum structural shapes, and ensure compliance with safety and regulatory standards. Their expertise can help optimize material selection, potentially saving costs and enhancing project outcomes.

In conclusion, choosing the right aluminum structural shape involves a careful evaluation of load-bearing needs, environmental conditions, and cost considerations. By understanding these factors and possibly consulting with experts, you can select the best aluminum shapes for your projects, ensuring durability, efficiency, and success.

Applications of Aluminum Structural Shapes in Modern Construction

Aluminum structural shapes have transformed modern construction and manufacturing, offering versatile solutions that meet the demands of contemporary design and engineering. Their applications extend across various industries, with a significant impact on construction, where their unique properties are leveraged to create innovative and sustainable structures.

Building Frames and Support Structures

In the realm of construction, aluminum shapes are extensively used in building frames and support structures. Their lightweight nature and high strength-to-weight ratio make them ideal for frameworks in skyscrapers and large commercial buildings. Imagine the ease of assembling a high-rise frame with materials that provide robust support without the burden of excessive weight. This not only facilitates quicker construction but also reduces the load on foundations, enhancing overall structural integrity.

Moreover, aluminum's corrosion resistance is a critical asset in construction, particularly for structures exposed to harsh weather conditions. Whether in coastal environments or industrial areas, aluminum shapes like beams and channels ensure longevity and reduce maintenance costs, making them a preferred choice for architects and engineers alike.

Architectural Design and Aesthetics

Aluminum shapes are not only functional but also contribute significantly to architectural design and aesthetics. Their malleability allows for intricate designs and custom extrusions that can enhance the visual appeal of buildings. From sleek, modern facades to decorative elements in interior spaces, aluminum's versatility supports creative architectural expressions. For instance, the use of aluminum panels and cladding in contemporary architecture provides a clean, modern look while offering excellent durability and energy efficiency.

Manufacturing and Industrial Applications

Beyond construction, aluminum structural shapes play a vital role in manufacturing, where they are used in creating machinery, transportation components, and more. The automotive industry, for example, utilizes aluminum shapes to manufacture lightweight vehicle parts, contributing to improved fuel efficiency and reduced emissions. In manufacturing plants, aluminum's excellent conductivity and heat resistance make it suitable for electrical components and heat exchangers, supporting efficient production processes.

In conclusion, the applications of aluminum structural shapes are vast and varied, spanning construction, manufacturing, and beyond. Their ability to combine strength, lightness, and aesthetic flexibility makes them indispensable in modern industry, driving innovation and sustainability in every project they touch.

Conclusion: The Future of Aluminum Structural Shapes in Sustainable Construction

The importance of aluminum structural shapes in modern construction and manufacturing cannot be overstated. As industries continue to evolve towards more sustainable and efficient practices, aluminum stands out as a key material driving this transformation. Its lightweight nature, combined with its strength and corrosion resistance, makes it an ideal choice for a wide range of applications, from skyscrapers to automotive components.

In the realm of sustainable construction, aluminum's environmental benefits are particularly noteworthy. Its recyclability and energy-efficient production methods significantly reduce its carbon footprint, aligning perfectly with the global push towards eco-friendly building practices. According to Golden Aluminum , the use of recycled aluminum can lead to substantial reductions in greenhouse gas emissions and energy consumption, making it a cornerstone of green construction initiatives.

Future Trends in Aluminum Material Science

The future of aluminum structural shapes is bright, with ongoing advancements in material science promising even greater innovations. As highlighted by Fortune Aluminum , the development of high-strength aluminum alloys and energy-efficient production technologies are set to revolutionize the industry. These innovations will not only enhance the performance and durability of aluminum shapes but also expand their applications across new sectors, including renewable energy and advanced manufacturing.

Furthermore, the integration of automation and Industry 4.0 technologies is streamlining the production of aluminum shapes, improving precision and reducing costs. This digital transformation is crucial for maintaining competitiveness in a rapidly changing global market, where efficiency and sustainability are paramount.

Sunmay: Leading the Charge in Aluminum Innovation

As we look to the future, companies like Suqian Sunmay Aluminium are at the forefront of this evolution, offering cutting-edge aluminum solutions that meet the highest standards of quality and sustainability. With a commitment to innovation and customer satisfaction, Sunmay is poised to lead the industry in developing cost-effective, high-performance aluminum products that cater to a diverse range of applications.

In conclusion, the role of aluminum structural shapes in sustainable construction is set to grow even further, driven by technological advancements and a heightened focus on environmental responsibility. As industries continue to embrace these changes, aluminum will undoubtedly remain a vital component in building a more sustainable and efficient future.

Frequently Asked Questions

1. What are the main types of aluminum structural shapes?

Aluminum structural shapes include standard types like channels, angles, beams, and bars. These are used for their strength-to-weight ratio and versatility in construction and manufacturing.

2. How do extruded aluminum structural shapes benefit custom designs?

Extruded aluminum shapes are customizable, allowing for precise cross-sectional profiles that meet specific project needs, enhancing strength and reducing joint requirements.

3. Why is aluminum preferred for structural applications?

Aluminum is lightweight, has a high strength-to-weight ratio, offers corrosion resistance, and is sustainable, making it ideal for structural applications in various industries.

4. How can an aluminum structural shapes catalog aid in project planning?

A catalog provides detailed specifications and dimensions of available aluminum shapes, helping in selecting the right materials for efficient and effective project execution.

5. What future trends are shaping the aluminum industry?

Advancements include high-strength alloys and energy-efficient production technologies, enhancing performance and expanding applications in sustainable construction and manufacturing.