Aluminum Pioneering Sustainable Innovation

Aluminum, a lightweight yet robust metal, has emerged as a cornerstone of modern industry, transforming sectors from construction and transportation to renewable energy. As a leading aluminum profile manufacturer, we recognize its critical role in fostering efficiency and sustainability.

Metallurgical Excellence

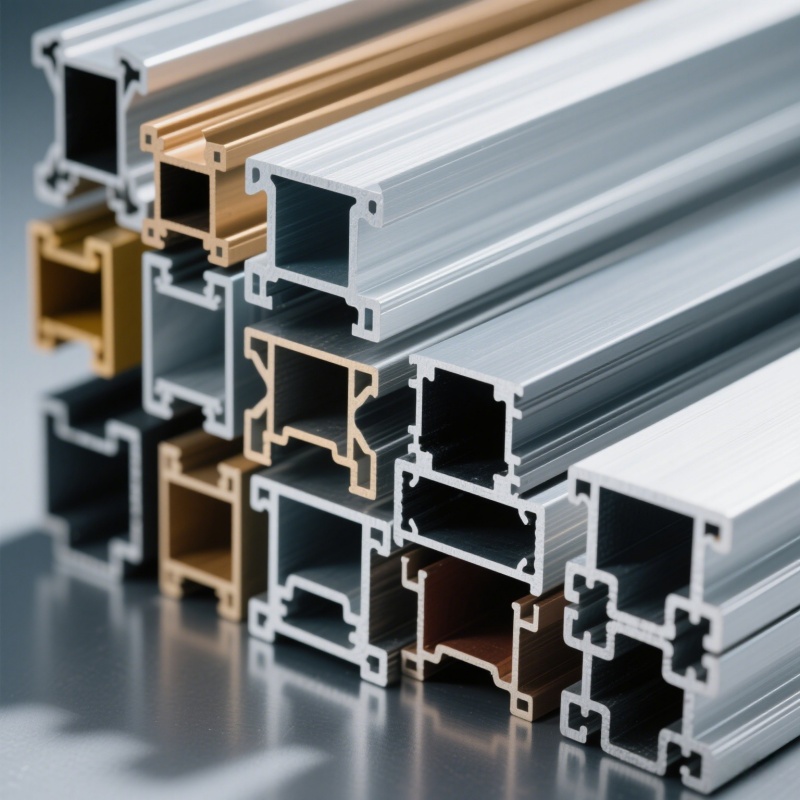

Aluminum’s face-centered cubic crystal structure grants it exceptional ductility and malleability, enabling it to be extruded into intricate profiles with minimal energy. Its natural oxide layer provides inherent corrosion resistance, reducing the need for protective coatings. With high thermal (237 W/m·K) and electrical conductivity (60.6% IACS), aluminum excels in heat exchangers, electrical wiring, and solar panel frames.

From Bauxite to Billet

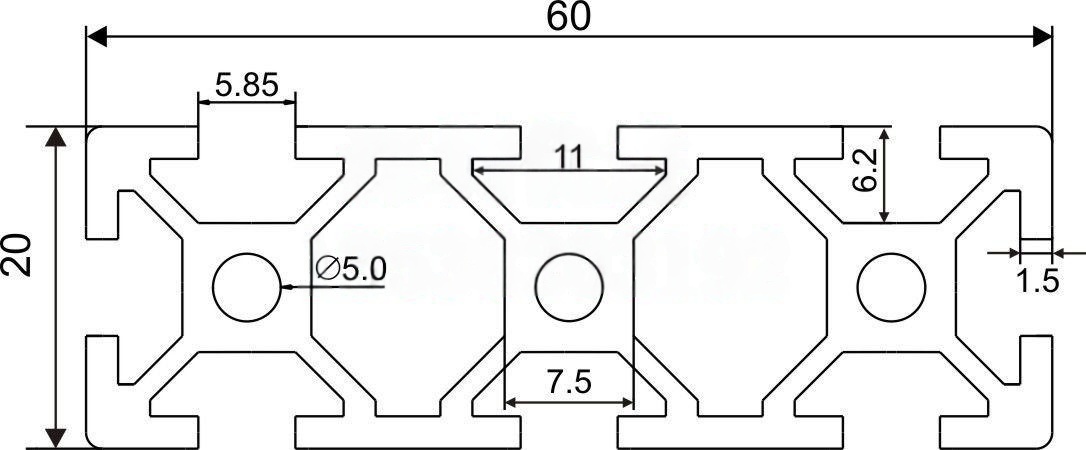

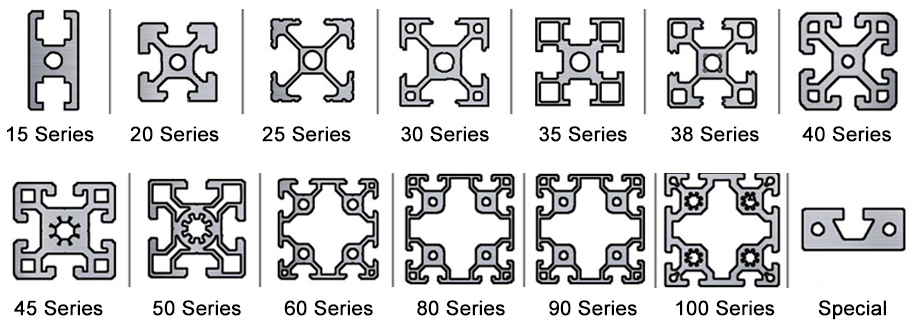

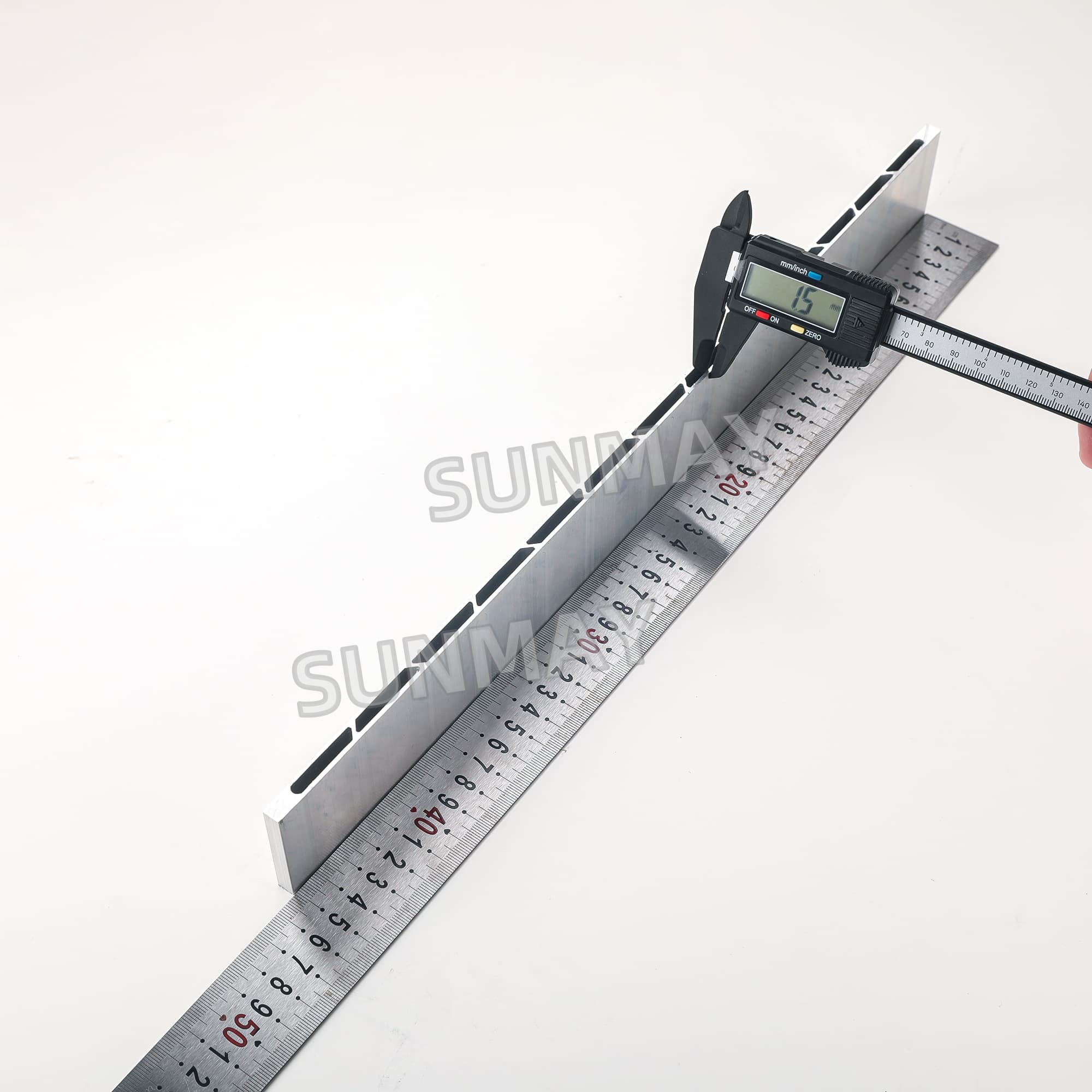

The production journey starts with bauxite mining, followed by the Bayer process to extract alumina. Electrolysis in Hall-Héroult cells then yields pure aluminum (99.5%+ purity), which is cast into billets. These are heated to 450-500°C and extruded through dies under high pressure, creating profiles with precise geometries. Anodizing, powder coating, or thermal breaks enhance durability, meeting diverse industrial demands.

Industry Transformations

1.Construction: Aluminum’s strength-to-weight ratio enables slender, high-rise structures while reducing transportation costs. Its recyclability (95% energy savings vs. primary production) aligns with green building standards.

2.Transportation:Lightweight aluminum improves fuel efficiency in automotive and aerospace, and electric vehicle batteries increasingly use aluminum casings for thermal management.

3.Renewable Energy: Solar panel frames and wind turbine components leverage aluminum’s corrosion resistance, supporting clean energy adoption.

4.Consumer Electronics: Aluminum enclosures in smartphones and laptops balance aesthetics with electromagnetic shielding, enhancing device performance.

Sustainability at the Core

Aluminum’s infinite recyclability positions it as a cornerstone of circular economies. Recycled aluminum requires only 5% of the energy needed for primary production, significantly cutting carbon emissions. Our manufacturing processes prioritize scrap recovery and closed-loop systems to minimize waste.

Challenges & Innovations

While aluminum production faces energy-intensive electrolysis and bauxite mining concerns, ongoing research focuses on inert anode technology to reduce emissions and carbon capture utilization to offset CO₂. The demand for ultra-high-strength alloys in electric vehicles and 5G infrastructure also drives innovations in alloy design and additive manufacturing.

As a trusted aluminum profile manufacturer, we are committed to delivering sustainable, high-performance solutions. By combining advanced metallurgy, precision engineering, and eco-conscious practices, we empower industries to innovate responsibly. Whether building greener cities, accelerating renewable energy, or enhancing everyday products, aluminum remains a metal of the future—one that balances progress with planetary stewardship.

At Foen, we invite you to explore how aluminum can transform your next project. Together, let’s build a lighter, brighter, and more sustainable world.